PEPS

Additional Modules

NC Program and

Drawing Management

CAMMAN is an easy-to-use data management system for the administration of NC programs, fixture plates and CAD data including SAP and ERP interfaces. The CAMMAN NC program management gives you easy access to existing data files and allows the input of extensive additional information, e.g. drawing number, order number, project number, version number, client, comment, date, programmer, machine as well as security confirmations for DNC Systems. The file selection is supported by an integrated 3D graphic viewer. By using the NC program, fixture plate and drawing management, the designer, the programmer and the machine operator share the same database, thus avoiding confusion and mistakes.

Individual adaptations and the connection to already existing databases are possible with CAMMAN.

Update check of CAD data in CAMMAN

From version 6.0 onwards, the CAD and NC program management CAMMAN will offer an update check of CAD data. To make sure that the generated NC programs are based on current CAD data, they will be checked for their up-to-dateness every time a PEPS file is opened. If the data have been modified in the meantime, a message will appear. PEPS visually displays the changes in the relevant part. Thanks to the fully automatic Feature Recognition WIRE-Expert, possible changes can be transferred quickly and correctly to the current program.

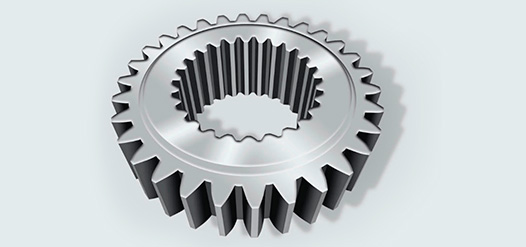

Gear Module

The Gear Module is used to calculate involute gears. The involute can be manipulated by entering a profile shift, the roller distance, testing mass across teeth, tip and root diameter as well as tip and root radii. Additionally, the Gear Module provides all the data and dimensions for machining and inspecting the gear.

The Gear Module is available as an option.

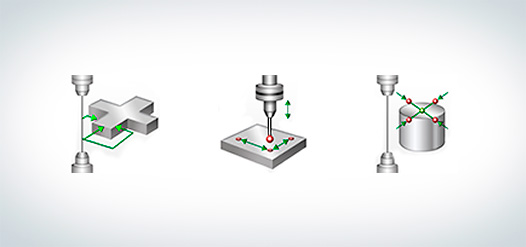

Measurement Cycles

Measurement cycles enable the exact calculation of the position of a workpiece before the part is machined. The control of measurement cycles via the NC program increases the accuracy of the parts and is fundamentally important in conjunction with handling systems.

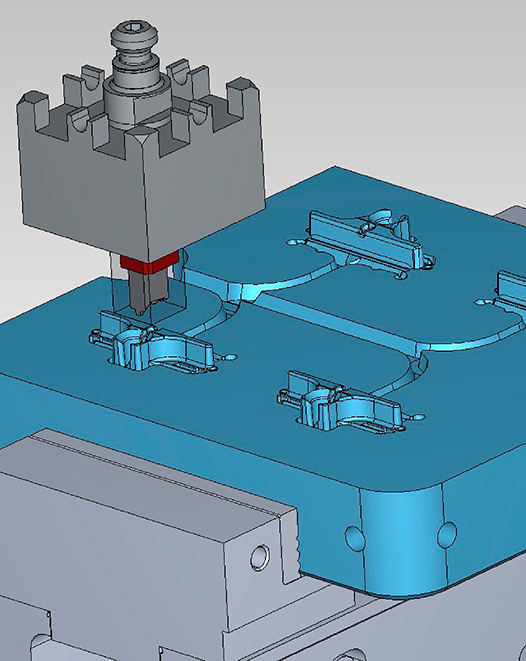

SolidElectrode

The SolidElectrode module is used for the creation of electrodes as well as for machining simulations with collision check. In conjunction with the corresponding postprocessor, it enables the creation of NC programs for vertical eroding machines.

- Derivation and archiving of 3D electrode geometries

- Modification of the electrode geometry

- Assigning the solid geometry of the electrode holder

- Archiving of electrode blanks

- Automatic creation of a measuring frame with alignment surface

- Placing the electrodes in the CAMMAN database, including additional information such as position, depth of erosion, electrode ident number, undersize, measurement data, program name, name of the roughing/finishing electrode as well as any additional information

- Automatic creation of a graphical setup sheet

JOBMAN 7.0

Job Manager in connection with automatic Nesting

The JOBMAN Job Manager creates nesting orders fully automatically. Parts of the same material and thickness are selected by JOBMAN and transferred to the Random Shape Nesting module. The parts to be machined are automatically selected from various orders and then nested on the sheet. With the JOBMAN Job Manager it is guaranteed that all parts of an order are made out of the correct material at the right time.

DNC systems for Windows

Safe data transfer between the server and the machine, including recharging.

- NC program transfer via intranet

- Integration into any network

- Direct call of the NC program files from the CNC control

- Support of standard and intelligent interfaces

- Uses software protocols for DNC-connections (e.g. Heidenhain, Deckel Maho, Mazak, AGIE, CHARMILLES)

- Forwarding of machine information via SMS or e-mail (optional)

Interfaces to PPS systems

Interfaces to all ERP/PPS systems, e.g. SAP, 3R Sigma, Zwicker, Schubert etc., are optionally available for CAMMAN and JOBMAN.

and without obligation.