PEPS

Laser & Water Jet Cutting

Performance strenth and efficiency.

2 axes laser, plasma and water jet cutting

These highly effective PEPS modules for 2D sheet metal working stand out due to an effective NC program creation and a very high automation level. CAD files are imported and adjusted, and a fully automatic nesting module ensures an optimum material utilization.

The expert system integrated into PEPS creates the machining features fully automatically based on default technology parameters. PEPS enables the NC program creation and machining simulation for machines of various manufacturers – including job management. Due to default priorities, urgently needed parts are machined first, despite full automation.

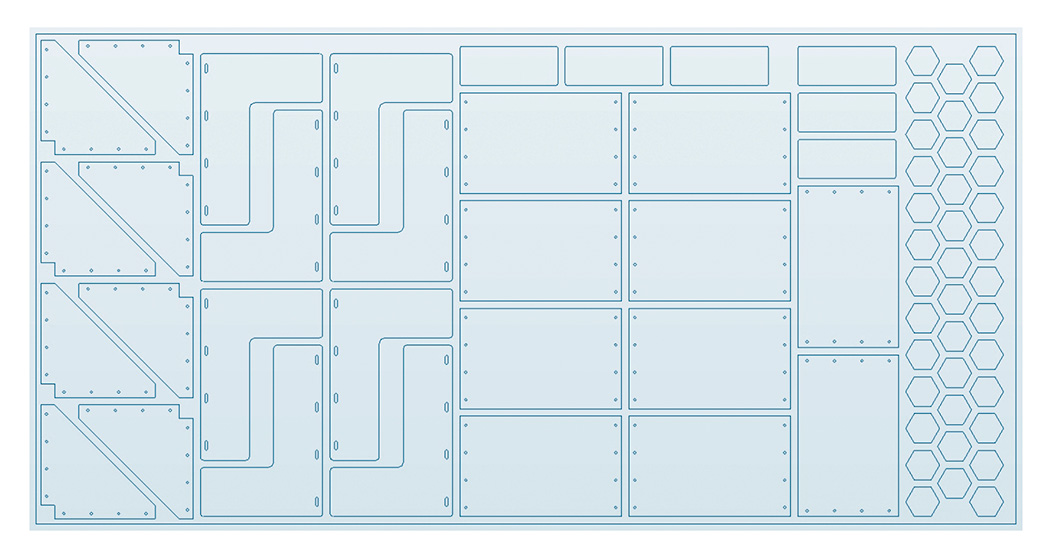

Cluster Nesting

Cluster Nesting enables semi-automatic nesting of parts on metal sheets and contains many functions that support the interactive nesting of parts.

During the semi-automatic distribution of geometries, a default distance between the parts and the edge of the sheet is maintained.

High Quality Random Shape Nesting

The fully automatic High Quality Random Shape Nesting places the parts on the metal sheet, depending on various parameters. Both the sizes of the metal sheets and the distances between the parts as well as the desired angular steps for the rotation of the parts can be taken into account. Filling parts are also defined, if required.

If there are a lot of different workpieces, the optimum utilization of the sheet will be calculated within a few seconds. The result can be further optimized with the specification of several nesting operations. All of this for an optimum material utilization.

The information regarding the parts to be nested can also be taken over from an already existing SAP/ERP system.

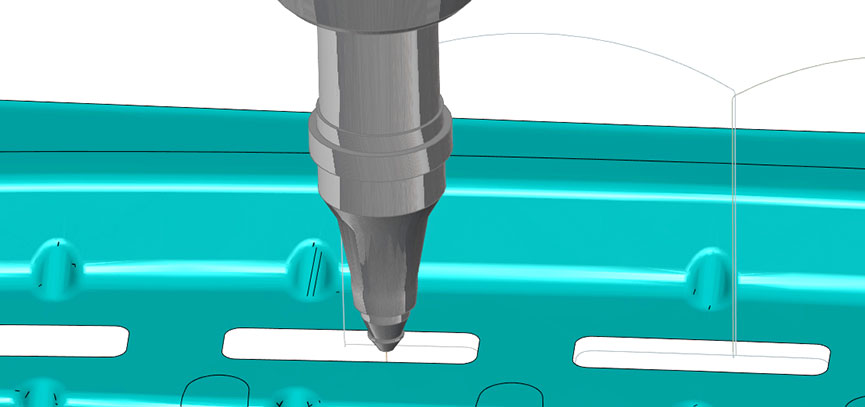

Complex, but still simple

The highly effective PEPS module CUT-Expert has been developed for the programming of complex laser and water jet cutting machines with up to 6 simultaneously controlled axes

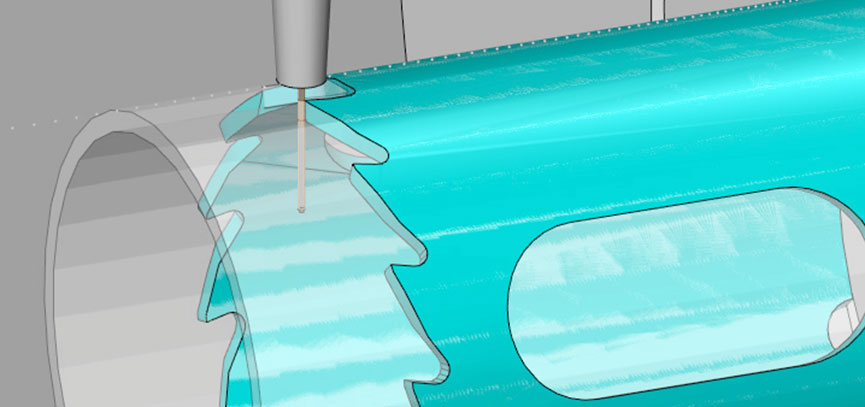

The simulation with collision check integrated into CUT-Expert ensures the necessary security of the machining process

CUT-Expert

6 axes simultaneous laser and water jet cutting

- Supports the programming of 5 axis machining as well as pipe and profile machining

- Automatic recognition of closed and open cutting contours

- Fast creation of machining features due to the usage of parameter sets that include all settings

- Technology selection from integrated technology database

- Easy editing of single, multiple or all cuts

- Control of the nozzle angle for the entire cut and for sections

- Calculation of angle bisectors for laser welding

- Simple enabling and disabling of cuts

CUT-Expert

Simulation

- 3D simulation, taking into account the machine kinematics

- Fully automatic collision check

- Simulation with material removal and variance analysis

and without obligation.